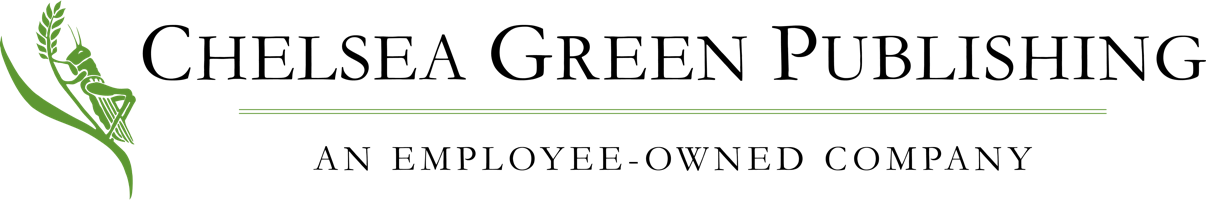

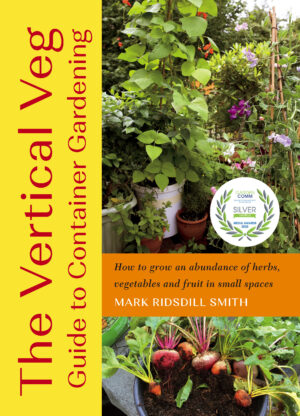

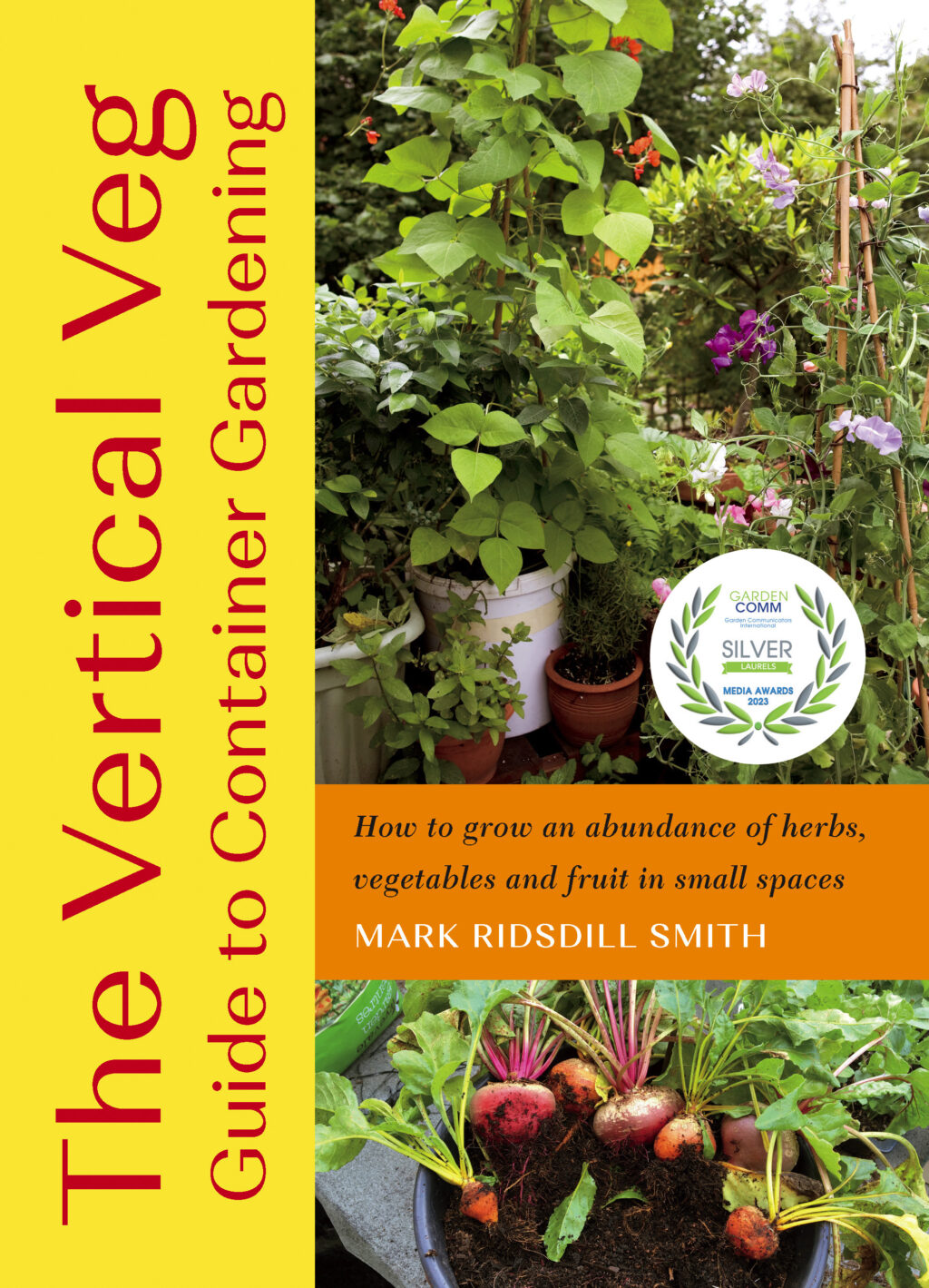

The Vertical Veg Guide to Container Gardening

How to Grow an Abundance of Herbs, Vegetables and Fruit in Small Spaces

EXCERPTS

| Pages: | 320 pages |

| Book Art: | Full-color photographs and illustrations throughout |

| Size: | 7 x 9.7 inch |

| Publisher: | Chelsea Green Publishing UK |

| Pub. Date: | March 24, 2022 |

| ISBN: | 9781645021506 |

The Vertical Veg Guide to Container Gardening

How to Grow an Abundance of Herbs, Vegetables and Fruit in Small Spaces

*Winner of the Garden Media Guild’s The Peter Seabrook Practical Book of the Year Award 2022

*2023 GardenComm Media Awards Silver Laurel Medal of Achievement

From the creator of the wildly popular website “Vertical Veg” and with over 200k people in his online community of growers, comes the complete guide to growing delicious fruit, vegetables, herbs, and salad in containers, pots, and more—in any space, from window boxes to garden yards, no matter how small!

“[A] thorough and enthusiastic guide to vegetable gardening . . . both handy and hefty…Aspiring urban gardeners will want to give this a look.”—Publishers Weekly

If you long to grow your own tomatoes, zucchini, or strawberries, but thought you didn’t have enough space, Mark Ridsdill Smith, aka the “Vertical Veg Man,” will show you how to make the most of walls, balconies, patios, arches, and windowsills.

Ridsdill Smith has spent over ten years teaching people to grow bountiful, edible crops in all kinds of containers in small spaces.

Inside The Vertical Veg Guide to Container Gardening, you’ll find:

- Mark’s “Eight Steps to Success”

- How to make the most of your space

- How to draw up a planning calendar so you can grow throughout the year

- Planting projects for beginners

- Compost recipes and wormery guide for the more experienced gardener

- Troubleshoots for specific challenges of growing in small spaces

- How growing food at home can contribute to wellbeing and the local community

With quick, proven results from his own tests, failures, and successes, Mark will show you how gardening in containers is not just a hobby, but a way of creating a significant amount of delicious, low-cost, high nutrition food.

Don’t be confined by the space you have—grow all the food you want with Mark’s Vertical Veg Guide to Container Gardening.

Awards

- 2023 GardenComm Media Awards Silver Laurel Medal of Achievement

Reviews and Praise

‘Mark’s enthusiasm is infectious and together with his attention to often-overlooked details, will give you confidence and knowledge to grow an impressive amount of food in seriously small spaces, where you probably thought you could not! He has been practising what he preaches for a long time and continually refines his methods, to be able to share with you many effective ways to harvest fresh vegetables throughout the year.’—Charles Dowding, author of Skills for Growing and No Dig Gardening

More Reviews and Praise

‘I love the image of many small urban gardens growing in containers – so useful and beautiful where water is available. There is a lot of good information in this book, whether you intend to make a container garden or sow plants in the ground. I know it will be a good guide for this (non-urban) gardener for years to come.’—Deborah Madison, author of An Onion in My Pocket and Vegetable Literacy

‘Mark has eliminated every excuse – you can garden wherever you live, without exception. He goes further than just salad greens by outlining a plan for most vegetables known to gardening. Despite the dedication, I contend that it will be as beneficial to those who want to container garden in the suburbs and the countryside as well as in the concrete jungle! We all are better off with this book. This book is detailed with many creative pointers gleaned from his years of experience container gardening. Fun to read.’—Peter Burke, author of Year-Round Indoor Salad Gardening

‘Food deserts and the associated human health concerns that exist in urban environments belie the costs of a failing food system. Growing fresh and nutritious produce in the city is a most important aspect of any food quality discussion. Vertical Veg provides ideas and guidance for the individual to create “a green oasis in a concrete space”. A simple pot of soil can support tasty herbs, salad greens and more. Mark Ridsdill Smith shows us how to take these ideas to the limits of available space, both his and his neighbors. These actions are infectious and inclusive – nourishing the body, nurturing the soul and connecting the community.’—Nigel Palmer, author of The Regenerative Grower’s Guide to Garden Amendments

‘The impression that the fine art of gardening can be achieved only by those with large amounts of space is slowly and surely becoming disproved. Mark’s container gardening book deals another major blow to that myth with a comprehensive guide, both practical and scientific, to growing edibles without the need for open ground. With many people in urban areas now living in flats, whose outdoor access is limited to balconies or small community areas, this book lays out with thorough advice how to garden in container conditions and how to enjoy the social, physical, and mental benefits of gardening with the massive bonus of having access to fresh food. What I most love about this book is that it is entirely based around Mark’s practical experiences – he is a container gardener to his soul, and whether you are an experienced gardener or just starting out, it is the perfect launch to your endeavours.’—Chris Collins, TV presenter and head of horticulture at Garden Organic

‘If you want bumper harvests from brick walls and block paving, this book shows you how. A cornucopia of sage advice and cunning tips, it's verbal fertiliser for your growing plans. But small space gardening is also about people, and Mark's considerate humanity blooms in every chapter.’—Tom Heap, BBC Countryfile

‘Mark has filled this book with so many insights from years of first-hand trial-and-error and building a real green community around growing food in challenging situations. I hope it inspires an army of urban vegetable growers to make the most of their outside spaces – I couldn't put this down.’—Sian Berry, Green Party member of the London Assembly

‘Like all the best educators Mark is an excellent storyteller, and his enthusiasm and personal commitment shine from every page.…

‘On a practical level this book details every important aspect of how to succeed growing in containers. From composting to watering, propagation to plant choices, there are detailed investigations and recommendations.…

‘Don’t be fooled by the ‘good for beginners’ intro. The depth of research and recording and the factual guidance is as good as it gets. This is a masterwork for all gardeners to enjoy – even the most experienced.’—Graham Bell, author, practicing gardener, teacher of permaculture

Reviews and Praise

‘Mark’s enthusiasm is infectious and together with his attention to often-overlooked details, will give you confidence and knowledge to grow an impressive amount of food in seriously small spaces, where you probably thought you could not! He has been practising what he preaches for a long time and continually refines his methods, to be able to share with you many effective ways to harvest fresh vegetables throughout the year.’—Charles Dowding, author of Skills for Growing and No Dig Gardening

‘I love the image of many small urban gardens growing in containers – so useful and beautiful where water is available. There is a lot of good information in this book, whether you intend to make a container garden or sow plants in the ground. I know it will be a good guide for this (non-urban) gardener for years to come.’—Deborah Madison, author of An Onion in My Pocket and Vegetable Literacy

‘Mark has eliminated every excuse – you can garden wherever you live, without exception. He goes further than just salad greens by outlining a plan for most vegetables known to gardening. Despite the dedication, I contend that it will be as beneficial to those who want to container garden in the suburbs and the countryside as well as in the concrete jungle! We all are better off with this book. This book is detailed with many creative pointers gleaned from his years of experience container gardening. Fun to read.’—Peter Burke, author of Year-Round Indoor Salad Gardening

‘Food deserts and the associated human health concerns that exist in urban environments belie the costs of a failing food system. Growing fresh and nutritious produce in the city is a most important aspect of any food quality discussion. Vertical Veg provides ideas and guidance for the individual to create “a green oasis in a concrete space”. A simple pot of soil can support tasty herbs, salad greens and more. Mark Ridsdill Smith shows us how to take these ideas to the limits of available space, both his and his neighbors. These actions are infectious and inclusive – nourishing the body, nurturing the soul and connecting the community.’—Nigel Palmer, author of The Regenerative Grower’s Guide to Garden Amendments

‘The impression that the fine art of gardening can be achieved only by those with large amounts of space is slowly and surely becoming disproved. Mark’s container gardening book deals another major blow to that myth with a comprehensive guide, both practical and scientific, to growing edibles without the need for open ground. With many people in urban areas now living in flats, whose outdoor access is limited to balconies or small community areas, this book lays out with thorough advice how to garden in container conditions and how to enjoy the social, physical, and mental benefits of gardening with the massive bonus of having access to fresh food. What I most love about this book is that it is entirely based around Mark’s practical experiences – he is a container gardener to his soul, and whether you are an experienced gardener or just starting out, it is the perfect launch to your endeavours.’—Chris Collins, TV presenter and head of horticulture at Garden Organic

‘If you want bumper harvests from brick walls and block paving, this book shows you how. A cornucopia of sage advice and cunning tips, it's verbal fertiliser for your growing plans. But small space gardening is also about people, and Mark's considerate humanity blooms in every chapter.’—Tom Heap, BBC Countryfile

‘Mark has filled this book with so many insights from years of first-hand trial-and-error and building a real green community around growing food in challenging situations. I hope it inspires an army of urban vegetable growers to make the most of their outside spaces – I couldn't put this down.’—Sian Berry, Green Party member of the London Assembly

‘Like all the best educators Mark is an excellent storyteller, and his enthusiasm and personal commitment shine from every page.…

‘On a practical level this book details every important aspect of how to succeed growing in containers. From composting to watering, propagation to plant choices, there are detailed investigations and recommendations.…

‘Don’t be fooled by the ‘good for beginners’ intro. The depth of research and recording and the factual guidance is as good as it gets. This is a masterwork for all gardeners to enjoy – even the most experienced.’—Graham Bell, author, practicing gardener, teacher of permaculture